Behind The Publication: Assessing transport phenomena in chemical plastic recycling

Shibashish Jaydev after successfully defending his PhD work at ETH Hönggerberg in September 2024.

In a recent publication, NCCR Catalysis researchers and colleagues highlight the importance of transport phenomena in chemical recycling of polyolefins and derive a metric for catalyst performance evaluation. Learn more about the work from Shibashish Jaydev in this Behind The Publication feature!

Could you tell us about yourself and the way toward this project?

I started at ETH Zurich as a Master’s student in 2018 and then decided to stay for a PhD. I had the pleasure of working on a variety of scientific topics, such as multiphase flows, microfabrication, cytometry and image processing. The common aspect of my student career was that I always wanted to try something new.

At some point, I felt I should come back to my core competence in chemical reaction engineering and approached Prof. Javier Pérez-Ramírez for a PhD position on the topic of chemical recycling of plastics. We decided to tackle polyolefins (polyethylene and polypropylene, comprising around 60% of all plastic waste), using an emerging route called hydrogenolysis, where hydrogen is also a reactant. After initially working on nanoscale catalyst design, we decided to shift our focus to the reactor scale due to the practical nature of the chemical recycling problem. With increasing scale, we realized that the reaction was heat and mass transfer limited, thereby hindering us from realizing the full potential of our catalysts. This led to the conception of this project to assess the influence of transport processes on catalyst effectiveness, which we could pursue thanks to an ETH Grant.

Prof. Javier Pérez-Ramírez, Shibashish Jaydev and Dr. Antonio José Martín Fernández from the aCe group at ETH Hönggerberg in September 2024.

What are the motivation and main results of this project?

In spite of designing and evaluating catalysts that showed great promise, we were convinced to be limited by factors at the reactor scale. The batch reaction we investigated involves three distinct phases, and can only take place when the hydrogen, the catalyst particles and the plastic molecules come together. This means the reaction had to be limited by transport processes, particularly mass transfer, owing to the high viscosity of the plastic melt. An easy way to show this was the changing catalytic performance with the stirring rate. As every research group working in this field uses a different setup, a different stirrer, there was no real way of assessing the extent to which external factors impacted the intrinsic catalyst performance. In this work, we present a means by which this can be done rather easily, independent of the setup or the catalysts.

Which was the main challenge? How did you address it?

Transport processes within a batch reactor system in plastic recycling could be influenced by a multitude of factors - viscosity, stirring speed, vessel dimensions, density and the extent of interfacial contact between the phases. The biggest challenge was to combine these factors into a single equation and present it in an accessible manner for other researchers. We addressed this by looking into possible dimensionless numbers that could help us account for all the factors at once. We thus arrived at a reinterpretation of the well-known power number, something other practitioners could also employ in their own research.

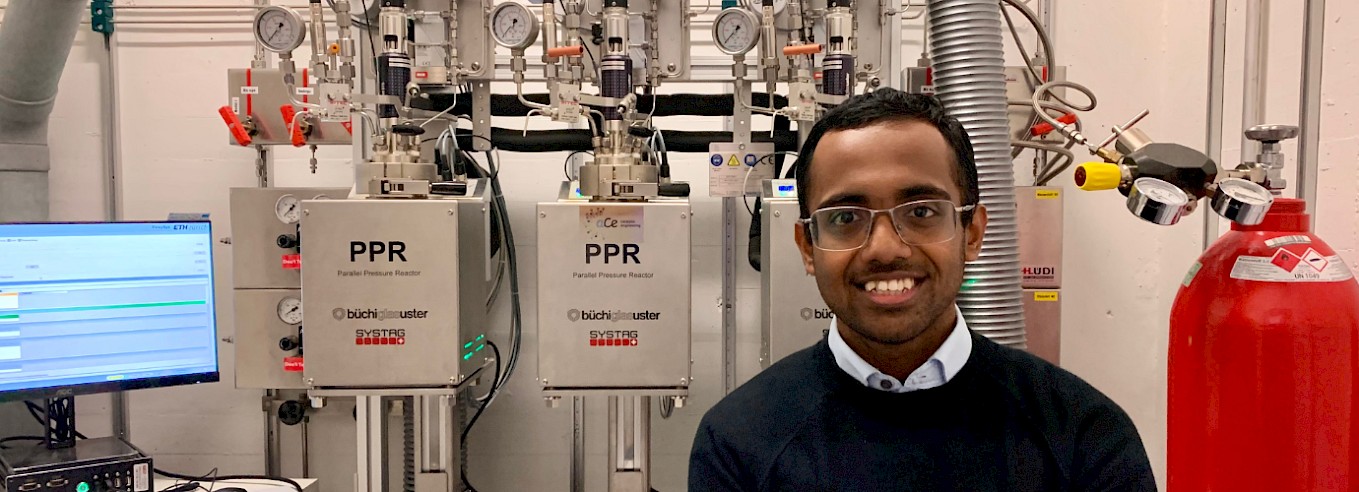

Shibashish Jaydev next to the parallel pressure reactor setup used in the study.

What impact did the ETH Grant have on this work?

As the ETH grant is awarded to high-risk, high-reward projects, the chemical recycling project was a perfect candidate. It provided us with the financial freedom to take risks in terms of exploring and pursuing radically innovative ideas in the initial phases of the project. We were able to expand the scope of our research in catalyst design and explore this reaction thanks to the support provided by the ETH grant.The solid foundation we could lay down owing to the ETH grant culminated in this project which, as a precursor, required access to superior catalysts, a sophisticated setup and other state-of-the-art technologies made possible through the grant.

What is your view on the integration of chemical recycling of plastics in Phase II of NCCR Catalysis?

The project, after its successful run so far, is now at a juncture where it requires multi-domain expertise and collaboration. It has now matured enough to need the involvement of more than one research group - material scientists to study rheology, chemists for operando studies, process and systems engineers for techno-economic studies and also social scientists for macro-level study of the plastic waste problem. I believe NCCR Catalysis offers this collaborative platform to exchange ideas and effectively tackle this multifaceted challenge. Besides, the platform also offers greater visibility to this research topic, inviting broader interests.

Polyolefins - among them polypropylene, which can be made into bottle caps - account for 60% of all plastic waste. © Shibashish Jaydev

What are your future, post-graduation plans?

Right after my PhD, I will start as an R&D Engineer in the chemical process development industry. Since my core interest lies in chemical engineering, I wish to continue working on the design of processes and reactors. I will, however, look to expand my knowledge in the direction of life cycle assessments and economic aspects of chemical processes. A long-term priority for me would be to maintain a solid work-life balance with a lot of sports and spending more time in the mountains.

Publication details:

Assessment of transport phenomena in catalyst effectiveness for chemical polyolefin recycling. S.D. Jaydev, A.J. Martín, D. Garcia, K. Chikri, J. Pérez-Ramírez. Nat. Chem. Eng. 2024, 1, 565. DOI: 10.1038/s44286-024-00108-3.

Link:

doi.org/10.1038/s44286-024-00108-3

ethz.ch/en/news-and-events/eth-news/news/2024/08/chemical-plastics-recycling-is-ready-to-go.html